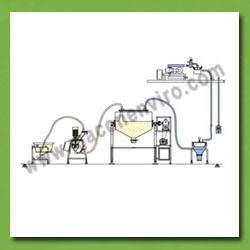

Powder Conveying System

We Macon Enviro Technologies as engaged in Manufacturers, Suppliers, Provider, Installation, Commissioning, Powder Conveying System. A powder conveying system, also known as a pneumatic conveying system, is a method used to transport powdered or granular materials from one location to another using air or gas as the conveying medium. It is commonly used in industries such as food processing, pharmaceuticals, chemical manufacturing, and plastics. This is the point where the powder or granular material is stored, such as a silo, hopper, or bulk bag. A network of pipes or tubes through which the material is transported. The pipeline is usually made of materials that can handle the abrasive nature of powders, such as stainless steel or hardened plastics. Compressed air or gas is used to create the necessary airflow for conveying the material. It can be generated by a blower or compressor. This component separates the conveyed material from the air or gas stream before it is discharged. It can be a cyclone separator, bag filter, or other types of filters depending on the specific requirements. The system is typically controlled by a central control panel or a programmable logic controller (PLC) that manages the airflow, pressure, and other parameters. Sensors and instruments are used to monitor the system and ensure proper operation. The final destination of the conveyed material, such as another storage vessel, processing equipment, or packaging machine.

In this method, the material is suspended in a high-velocity air stream, typically at low pressure. It is suitable for conveying powders over long distances and at high rates. Here, the material is conveyed as a slower-moving, high-density plug or slug within the pipeline. Dense phase conveying is often used for fragile or abrasive materials that require gentle handling. This system uses a vacuum pump to create suction and transport the material. It is commonly used for transferring powders from smaller containers or for loading material into processing equipment. The choice of the powder conveying system depends on factors such as the nature of the material, distance of conveying, required throughput, and specific process requirements. Proper design, including the selection of pipeline diameter, airflow rates, and appropriate control systems, is crucial to ensure efficient and reliable operation. We at Macon Enviro Technologies are committed to providing a large selection of Powder Conveying System to our esteemed clients In Mumbai, Navi Mumbai, Thane and around India.