Dense Phase Pneumatic Conveying System

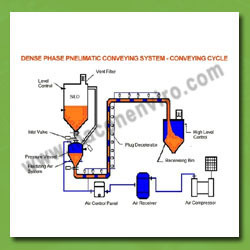

We Macon Enviro Technologies as engaged in Manufacturers, Suppliers, Provider, Installation, Commissioning, Consultant Dense Phase Pneumatic Conveying System A dense phase pneumatic conveying system is a method used to transport bulk materials, such as powders, granules, or other solid materials, through a pipeline using a gas or air flow. Unlike dilute phase conveying, where the material is suspended in a high-velocity air stream, dense phase conveying operates at lower velocities and higher pressures, resulting in a higher material-to-air ratio. In a dense phase pneumatic conveying system, the material is transported in a slug or plug flow, where the material moves as a compact mass with minimal particle-to-particle interaction. This mode of conveying offers several advantages, including reduced material degradation, lower energy consumption, and the ability to convey materials over longer distances. The bulk material is typically fed into a pressure vessel or hopper, which acts as a reservoir. The feeding can be done manually or by using equipment like screw feeders or rotary valves. A high-pressure air or gas source is used to pressurize the vessel, creating the driving force for conveying the material. Compressed air or an inert gas, such as nitrogen, is commonly used. When the pressure vessel reaches the desired pressure, a discharge valve or other controlled mechanism is opened to release the pressurized material into the pipeline.

The material moves in a dense slug or plug flow, driven by the pressure difference between the vessel and the pipeline. The pipeline is designed to accommodate the dense phase flow of the material. It typically consists of smooth bends and horizontal sections to minimize pressure drop and avoid material buildup or blockages. The pipeline may also include features like air injectors or flow aids to ensure proper material flow. Once the material reaches its destination, it is separated from the conveying gas using a receiver or cyclone separator. The separated material can be collected for further processing or storage, while the conveying gas is recycled back into the system. Dense phase pneumatic conveying systems are commonly used in various industries, including food processing, chemical manufacturing, pharmaceuticals, and mining, where the gentle handling of materials and precise control of the conveying process are crucial. It's important to note that the design and operation of a dense phase pneumatic conveying system can vary depending on the specific application, material characteristics, desired conveying capacity, and other factors. Consulting with experts or specialized engineers is recommended for designing and implementing an efficient and reliable system. We at Macon Enviro Technologies are committed to providing a large selection of Dense Phase Pneumatic Conveying System to our esteemed clients In Mumbai, Navi Mumbai, Thane and around India.